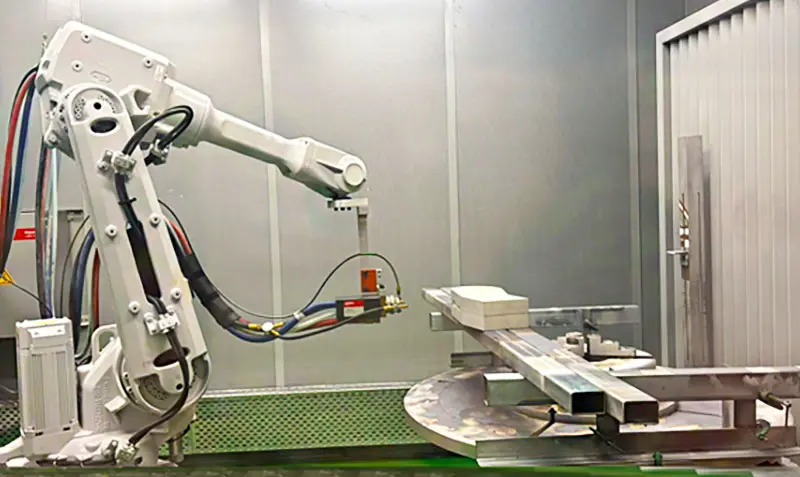

Plasma spraying is a surface enhancement and modification technique that endows substrates with properties such as wear resistance, corrosion resistance, high-temperature oxidation resistance, electrical insulation, thermal insulation, radiation protection, reduced friction, and sealing. The process employs a plasma arc, driven by direct current, to heat materials such as ceramics, alloys, and metals to a molten or semi-molten state, which are then sprayed at high speed onto the pre-treated surface of a workpiece to form a well-adhered surface layer.

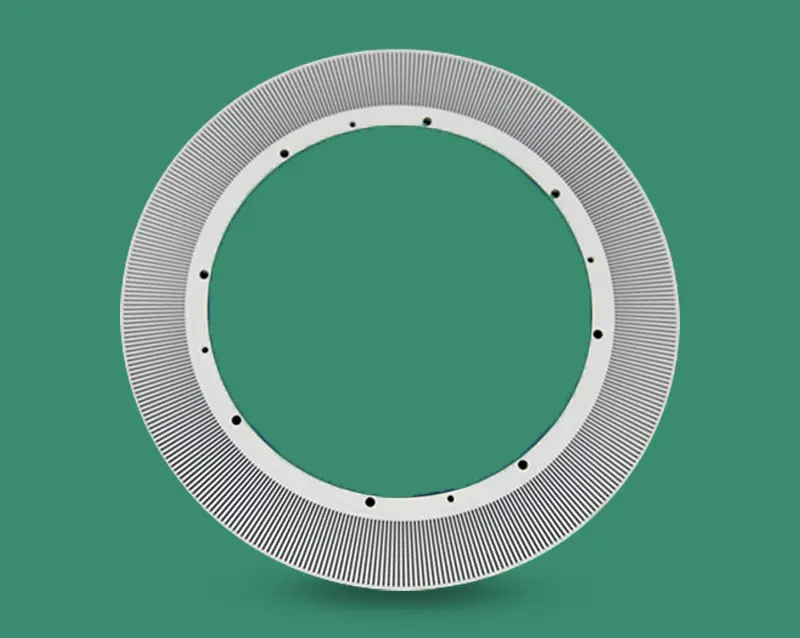

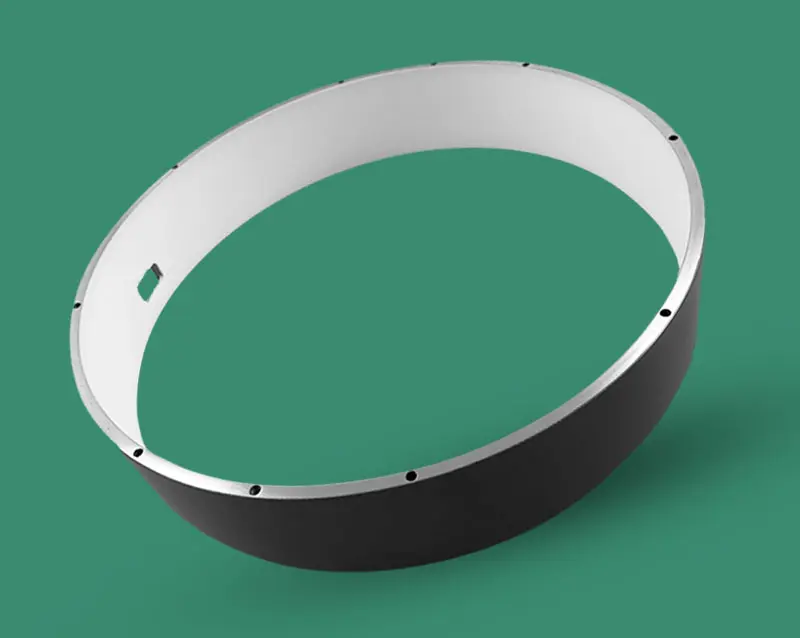

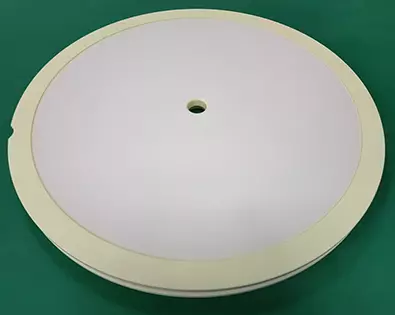

Coating Specifications and Testing

| Coating Indicators | Yttrium Oxide | Alumina | Testing Methods |

| Thickness | <0.5mm | <0.5mm | Micrometer & Film Thickness |

| Surface Roughness | 4.0~6.0μm | 4.0~6.0μm | Roughness Tester (Profilometer) |

| Microhardness | 400~600HV | 800~1000HV | Metallographic Analysis (Microhardness Tester) |

| Porosity | <3% | <3% | Metallographic Analysis (Image Analysis) |

| Bonding Strength | >20Mpa | >20Mpa | Tensile Test (Adhesives) |