Silicon Carbide

-

Silicon Carbide

Silicon carbide(SiC) ceramics are materials with high fracture toughness and excellent thermal shock resistance, boasting outstanding mechanical properties, good oxidation resistance, high wear resistance, and a low friction coefficient.

-

Material Properties

- High Mechanical Strength

- Wear Resistance

- High Thermal Conductivity

- Corrosion Resistance

-

Applications

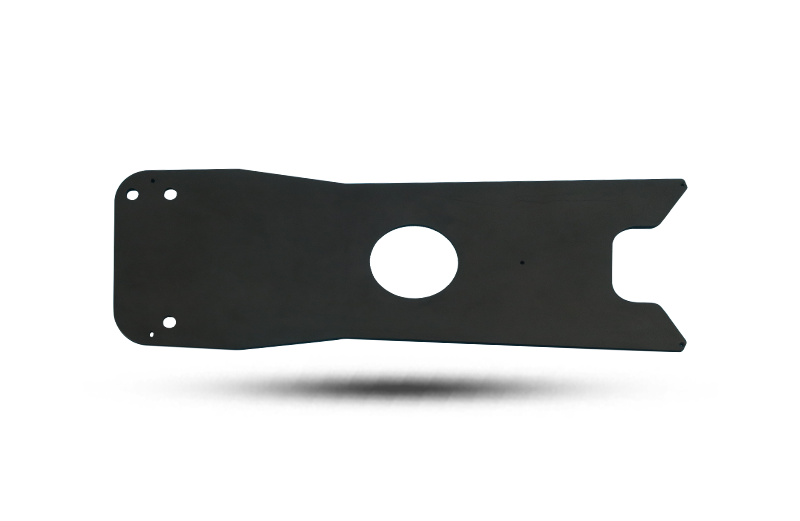

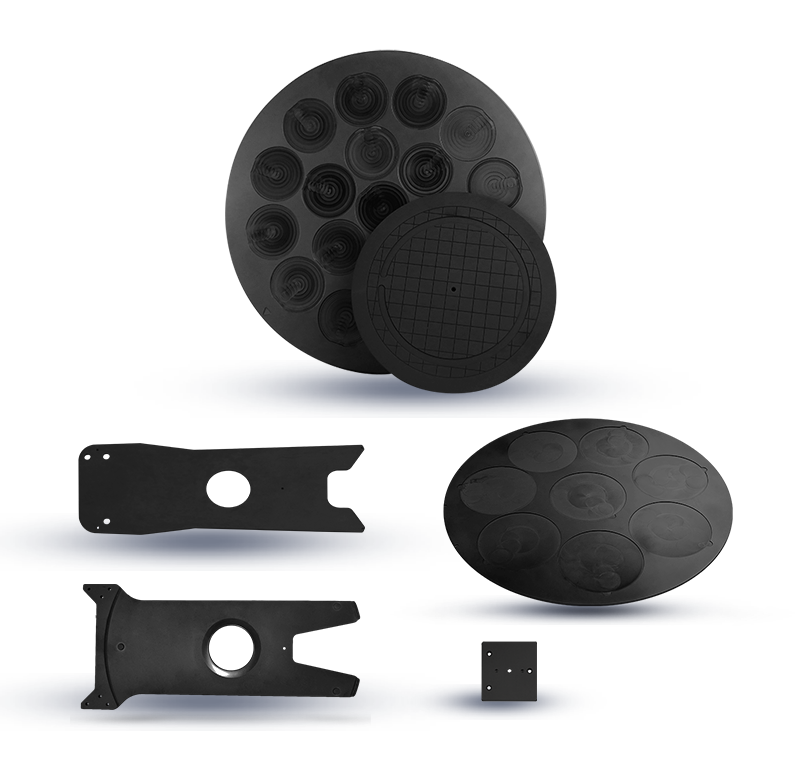

Ceramic End Effector

Silicon carbide ceramic end effectors are lightweight and resistant to high temperatures, abrasion, and corrosion, ideal for wafer handling in the semiconductor industry. They offer thermal stability and anti-static performance, ensuring safe and reliable advanced manufacturing.

Customizable Machining

Reverse engineering from drawings and samples.

Rings

With good hardness and wear resistance, it is ideal for grinding and cutting. Its high corrosion resistance makes it preferred in the chemical and metallurgical industries. It is available in various specifications.

Customizable Machining

Reverse engineering from drawings and samples.

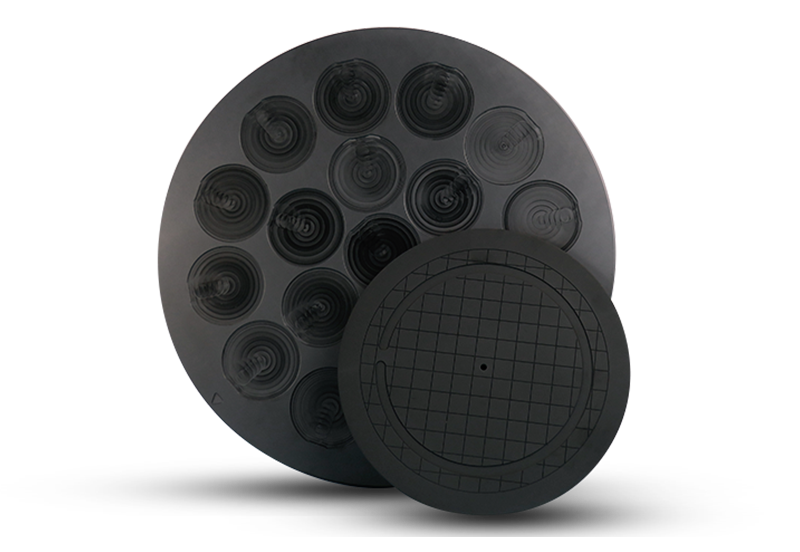

Ceramic Carrier

These carriers support and protect wafers and chips in critical semiconductor manufacturing processes such as high-temperature heat treatment, CVD, MOCVD, etching, and gas deposition, ensuring efficiency and stability. JFM specializes in providing customized solutions for high-performance ceramic components.

Customizable Machining

Reverse engineering from drawings and samples.

Silicon Carbide Base

Silicon carbide base offers high purity, good thermal conductivity, and strong corrosion resistance, making them ideal for semiconductor deposition processes and effective in supporting wafers. They are also widely used in electronics, optoelectronics, and the automotive industry.

Customizable Machining

Reverse engineering from drawings and samples.