Why Ceramic Nozzles are Essential for Semiconductor Plasma Etching Equipment

High-purity ceramic nozzles stabilize gas flow and plasma distribution in semiconductor etching. Their superior heat and corrosion resistance minimize contamination, extend component life, and boost wafer yields while reducing maintenance costs.

Semiconductor Ceramic Nozzles :Material Types and Selection Guide

A technical guide to ceramic nozzle materials for plasma etching. Learn to select the right Alumina, AlN, or ZrO₂ components to enhance precision, durability, and production yield in microelectronics manufacturing.

How Ceramic Chambers and Domes Enhance Semiconductor Manufacturing Yield

Ceramic chambers and domes resist extreme heat and plasma to ensure process stability. Their thermal uniformity and corrosion resistance minimize contamination, directly boosting film quality and manufacturing yield.

Why Alumina (Al₂O₃) is the Preferred Choice for Industrial Chambers & Domes

Alumina ceramics offer exceptional thermal stability, chemical resistance, and electrical insulation. These properties ensure long-lasting, high-performance chambers and domes for semiconductor manufacturing and plasma etching.

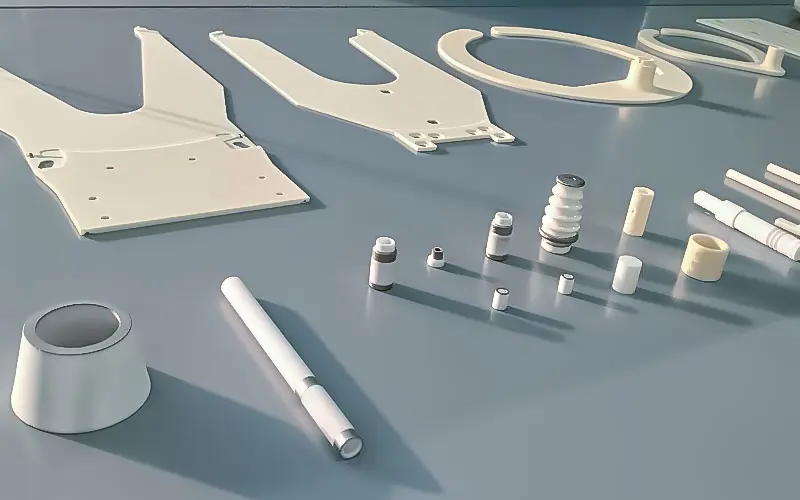

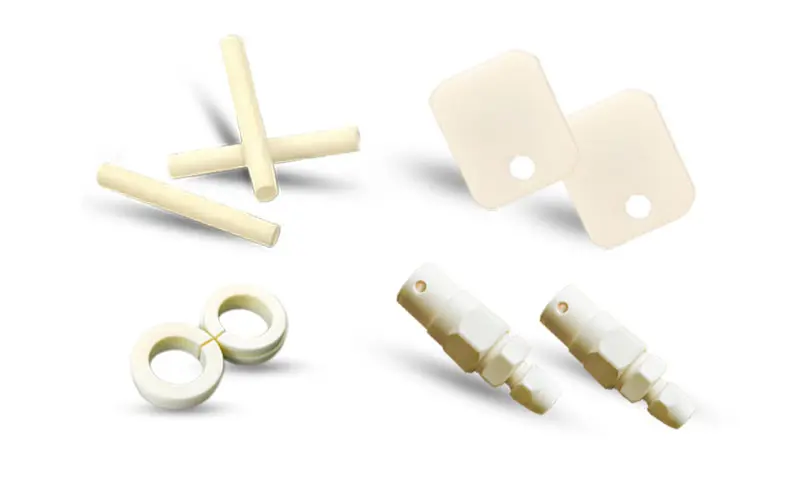

Industrial Applications of Structural Ceramics

What are structural ceramics? Discover how structural ceramics, with their unparalleled durability and strength, enhance performance across aerospace, energy, and manufacturing industries.

Applications of Semiconductor Ceramics in Modern Chip Manufacturing

Advanced ceramic materials play a critical role in semiconductor manufacturing by enabling chip stability and long-term reliability.

Alumina Ceramics in Biomedical and Clinical Applications

Why do surgeons and engineers trust alumina ceramics? Because they stay stable in the body, resist wear, and perform reliably for years—especially in joint replacements and dental restorations.

What Are Fine Ceramics? Types and Applications

This guide explains what fine ceramics are, how their microstructure drives performance, common material types, manufacturing processes, and where they’re used—from semiconductors and electronics to life science, automotive, and energy.

What Are the Uses of Alumina?

Alumina, also known as aluminum oxide, is a versatile ceramic material widely used across modern industry. This article explores its main applications and uses.