Porous Ceramic

-

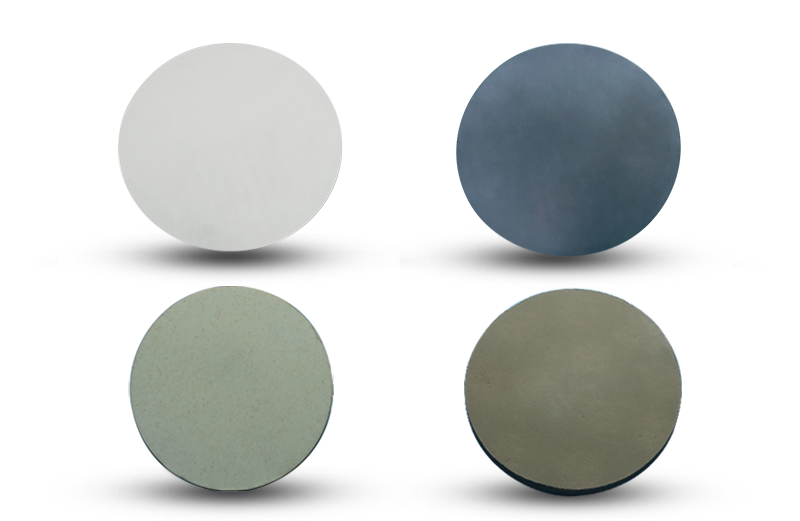

Porous Ceramic

Porous ceramics, made from high-quality materials like alumina, silicon carbide, and cordierite, undergo precise powder preparation, molding, and high-temperature sintering to achieve adjustable pore sizes from nano to micrometers. This material excels in manufacturing products like vacuum suction cups, providing uniform airflow distribution for precision applications such as semiconductor wafer production and ensuring stability and reliability during the adsorption process.

-

Material Properties

- High Temperature Resistance

- High Pressure Resistance

- Corrosion Resistance

- Good Biocompatibility

- Long Service Life

- Controllable Microporous Structure and Porosity

- Good Mechanical

-

Applications

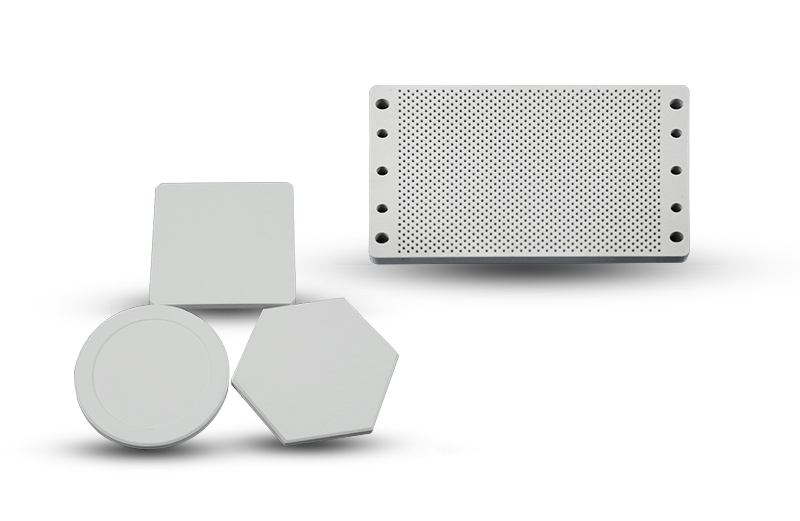

Porous Ceramic Disc

JFM specializes in the R&D and design of porous ceramics, offering customized solutions tailored to client requirements. We address diverse application needs - from pore size, porosity, and dimensional specifications to material composition and performance criteria. JFM's porous ceramic substrates are widely utilized in vacuum chucks, filtration systems, and catalyst carriers, earning client trust through quality and reliability.

Customizable Machining

Reverse engineering from drawings and samples.

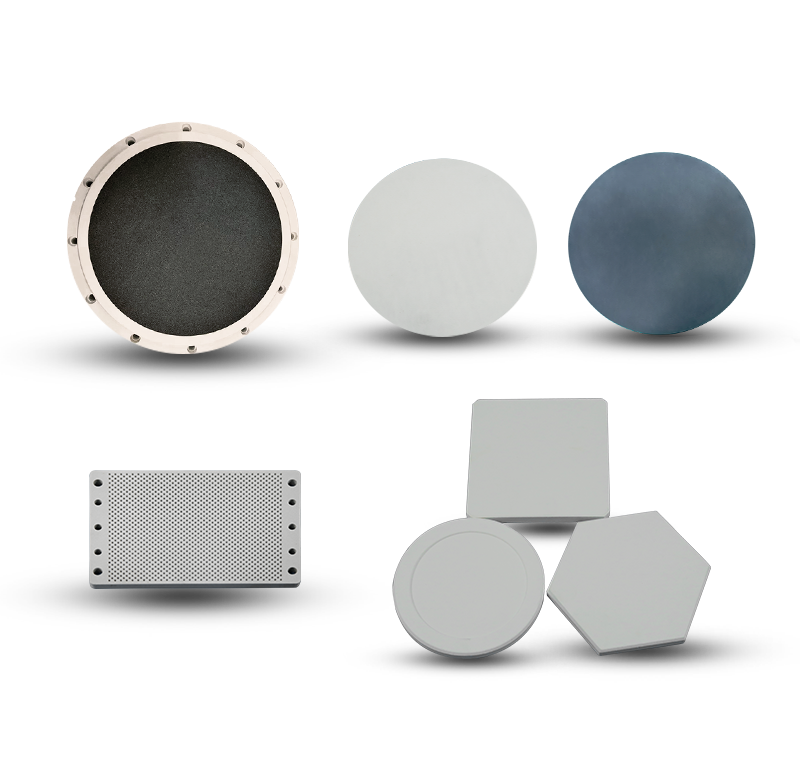

Custom Parts

JFM specializes in custom porous ceramic parts, offering tailored solutions through reverse engineering from design drawings or physical samples. Our products, including diatomaceous earth drying plates and zirconia-bonded porous ceramics, are widely used in drying, filtration, and catalysis applications.

Customizable Machining

Reverse engineering from drawings and samples.