01Cleanable Materials

- Metal and Alloy

- Ceramic

- Quartz

- Glass

- Sapphire

- Polymer

- Silicon

- Coated Parts

02Removable Pollutants

- Organic Compound

- Oxide

- Hydrocarbon

- Particle (submicron)

- Oil

- Grease

- Hydroxide

- Thin Film

- Inorganic Substance

- Coating

- Metal

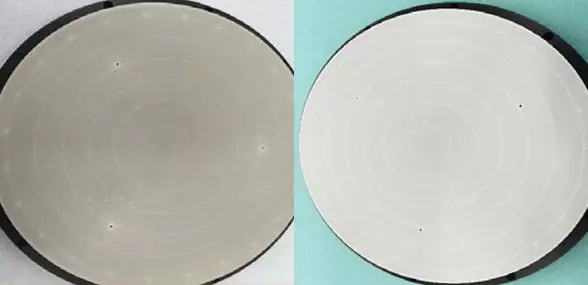

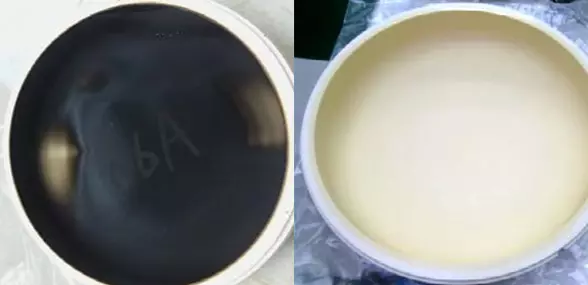

03Cleaning Method

- Chemical Cleaning

- Degreasing

- Oxidizing/Reducing Agent

- Alkali/Acid Etchant

- Deionized Water Cleaning

- Selective Etching

- Physical/Mechanical Cleaning

- High Pressure

- CO2 Cleaning

- Sandblasting

- Ultrasonic Cleaning

- Polishing

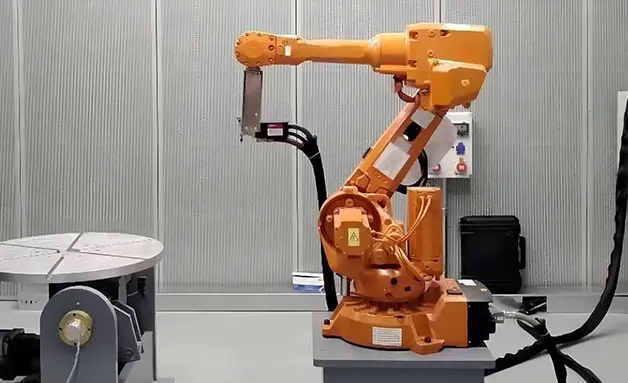

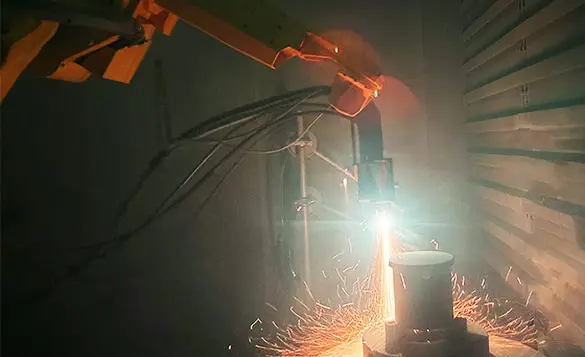

- Arc Spraying