-

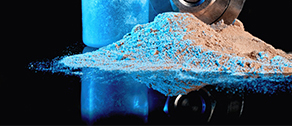

Materials

-

Applications

Semiconductor Machinery&Equipment -

Customizable Machining

Reverse engineering from drawings and samples.

-

Product Description

JFM specializes in the precision manufacturing of stainless steel metal end effectors, ensuring high accuracy and quality through advanced machining techniques. They are widely used in the semiconductor, particularly for wafer handling and cutting in corrosive gas environments, as well as various applications in machinery. We offer tailored solutions to meet specific customer requirements for diverse applications.

-

Product Properties

- Good Thermal Conductivity

- High Strength

- Corrosion Resistance

- Good Mechanical Properties

- Good Conductivity