Why Alumina Ceramics Are Essential in Advanced Manufacturing Industries?

- 2025-12-27 Industry News

Why are alumina ceramics widely used in advanced manufacturing? This article explains what alumina ceramics are, their key properties, and typical applications.

Introduce

In today’s advanced manufacturing industries, aluminum oxide ceramics (Alumina Ceramics) are widely recognized as a “fundamental yet critically important material.” Alumina combines high mechanical strength, excellent heat resistance, electrical insulation, and chemical stability (inertness), making it an indispensable engineering ceramic for industries with demanding material requirements. Typical applications include sealing substrates for IGBT modules, biomedical implants, optical windows for high-power lasers, and chamber components for plasma etching equipment, where metals and polymers often cannot deliver comparable performance.

What Are Alumina Ceramics (Al₂O₃)?

Alumina Ceramics (Aluminum Oxide Ceramics) are structural–functional engineering ceramics primarily composed of aluminum oxide (Al₂O₃), manufactured through high-temperature sintering. With excellent mechanical properties—especially high hardness and outstanding wear resistance—alumina maintains stable performance even under harsh operating conditions.

Additionally, material properties can be tailored by adjusting the purity of alumina, allowing for application-oriented control of structural strength, chemical stability, and electrical insulation. A typical industrial classification is as follows:

|

Category |

Alumina Purity (%) |

Main Application Areas |

|

Standard Alumina Ceramic |

85–95 |

General-purpose parts such as valve bodies, nozzles, and insulators |

|

High-Purity Alumina Ceramic |

≥99.5 |

Semiconductor packages, biomedical ceramics, and laser resonator components |

|

Ultra-High-Purity Alumina Ceramic |

≥99.99 |

Optical windows, high-energy accelerators, and IC packages |

Alumina typically has a hexagonal close-packed crystal structure (α-phase), forming a stable mixed covalent–ionic bonding network with high symmetry. This microstructure enables key properties such as high hardness, a high melting point (about 2050°C), high electrical resistivity and dielectric strength, and strong resistance to various corrosive environments.

Aluminum oxide ceramics also offer excellent forming and processing flexibility. They can be produced via dry pressing, slip casting, hot pressing, cold isostatic pressing (CIP), and 3D Printing, among other methods. With widely available raw materials, stable pricing, and strong design freedom, alumina is one of the most broadly adopted materials in industrial ceramics.

Outstanding Mechanical Performance— Built for High-Wear and High-Load Environments

Thanks to its exceptional mechanical performance, aluminum oxide ceramics clearly stand out in harsh operating environments. For applications requiring wear resistance, compressive strength, and durability under load, alumina often outperforms metals and engineering plastics, delivering long-term reliability and service life.

|

Item |

Typical Range |

Notes |

|

Mohs Hardness |

8.5–9 |

Extremely high hardness |

|

Compressive Strength |

2000–3000 MPa |

Far exceeds many common metal materials |

|

Flexural Strength |

300–600 MPa |

Can be improved via purity and sintering conditions |

|

Young’s Modulus |

≥300 GPa |

Comparable to steel, yet lightweight |

|

Density |

3.8–3.9 g/cm³ |

Suitable for lightweight structural components |

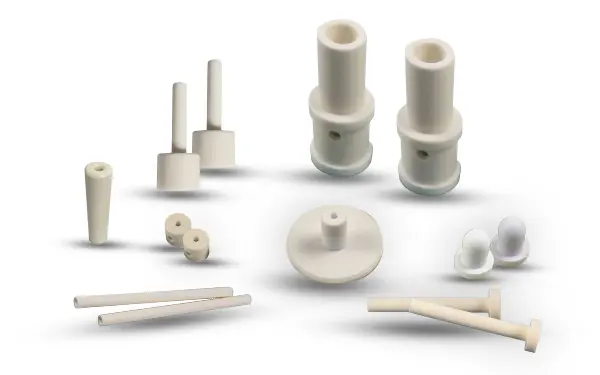

Leveraging this combination of high hardness and high strength, alumina plays a key role as a structural material in high-wear and high-load environments. For example, alumina blades are used in high-hardness cutting applications, while alumina plungers are used for sealing and pressurizing in high-pressure fluid pumps and chemical equipment.

Excellent Electrical Insulation — A Foundation for High-Voltage and High-Frequency Applications

Among non-metal materials, aluminum oxide ceramics (Al₂O₃) have established themselves as indispensable in electrical, electronic, microwave communication, and power device fields, thanks to their extremely high volume resistivity, low dielectric loss (tan δ), and high dielectric breakdown strength. From high-voltage environments to high-frequency pulsed electric fields, alumina delivers stable electrical performance over long operating periods. Its application range is broad: high-voltage insulators, inductor supports, IGBT module substrates, RF device components, insulating sleeves, socket bases, and more. For instance, alumina rods are used as insulating supports inside RF equipment, helping ensure stable high-frequency signal transmission and suppressing noise.

Exceptional Chemical Stability — Reliable Even in Corrosive and Plasma Environments

Aluminum oxide ceramics maintain stability in many acids, alkalis, molten metals, and processing atmospheres, and are widely used in highly corrosive environments such as etching reaction vessels, nuclear components, and metallurgical nozzles.

● Chemically inert: Remains unreactive over extended periods in many acid/alkali solutions, and retains structure even in media such as concentrated sulfuric acid (H₂SO₄), sodium hydroxide (NaOH), and hydrochloric acid (HCl). For example, alumina nozzles can be used continuously in corrosive chemical-industry environments.

● Excellent oxidation resistance: Surface oxidation and phase rearrangement are unlikely even under high-oxygen conditions.

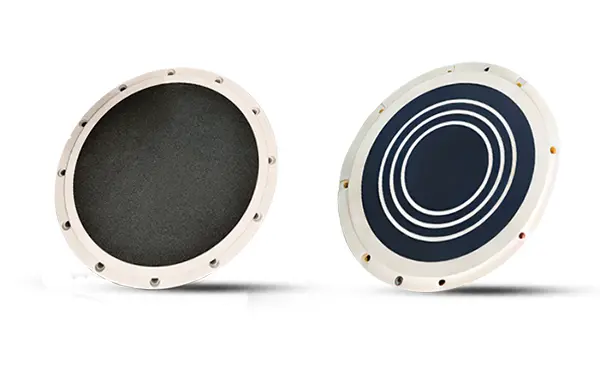

● Strong plasma resistance: Does not easily powder or undergo gas reactions in plasma environments such as semiconductor etching, making it an ideal material for high-purity process chambers. For example, alumina vacuum chucks are well-suited for precision adsorption of semiconductor wafers.

● No volatile element release: Meets usage standards for ultra-high purity, vacuum, and high-energy physics equipment and does not contaminate the system.

With these highly stable chemical properties, aluminum oxide ceramics are well-suited for environments sensitive to corrosion and contamination, as well as high-energy reaction conditions. For example, alumina vacuum chucks used in semiconductor manufacturing can withstand environments with strong acids and strong alkalis, enabling stable operation.

Excellent Adaptability in Machining and Forming

Contrary to the traditional impression that “ceramics are difficult to machine,” aluminum oxide ceramics in real industrial applications offer strong process adaptability and forming flexibility. From mass production of standard parts to custom support for highly integrated components with complex geometries, alumina can meet a wide range of needs.

|

Forming Method |

Key Advantages |

Typical Applications |

|

Dry Pressing |

High precision and low shrinkage; suitable for mass production of small to medium parts |

Ceramic substrates, cylindrical shells, insulating sheets, etc. |

|

Cold Isostatic Pressing (CIP) |

Uniform pressure enables higher density, suitable for high-strength parts |

Optical windows, valve cores, etc. |

|

Slip Casting / Tape Casting |

Supports hollow and complex shapes; suitable for large and thin-wall structures |

Laser resonators, equipment covers, pump casings, etc. |

|

Gel Casting |

Porosity can be controlled, making it suitable for filtration/adsorption functional ceramics. |

Ceramic membranes, molecular sieve supports, etc. |

|

3D Printing |

Ideal for small batches and short lead times, enabling designs that transcend conventional shape constraints |

Biomedical implants, custom parts, and integrated products with fine microstructures, among others. |

Although alumina is inherently brittle, advances in ceramic machining technology now enable micron-level precision processing.

● Supports advanced processes such as laser engraving, CNC grinding, ultrasonic drilling, and precision polishing

● Dimensional accuracy and surface roughness can be customized

● Can handle complex geometries such as thin walls, intricate recesses, and microfluidic channels

Environment-Friendly and Sustainability-Oriented Advantages

With “carbon neutrality” goals and the acceleration of green manufacturing, the materials industry faces the challenge of balancing performance with environmental responsibility. Aluminum oxide ceramics attract attention from both policy and market perspectives due to their strong performance and relatively low environmental footprint.

● Green-material characteristics

Aluminum oxide ceramics are non-toxic and harmless, containing no hazardous substances. After disposal, they can be reused through high-temperature treatment. Their excellent wear and corrosion resistance, as well as their long service life, also help reduce resource consumption and waste generation.

● Greener manufacturing processes

Traditional organic forming agents are being increasingly replaced with water-based binders, which significantly reduce volatile organic compound (VOC) emissions. In addition, new sintering technologies, such as microwave sintering and plasma-assisted sintering, are being introduced, continuously reducing energy consumption and carbon emissions.

Furthermore, integrating clean energy sources such as solar and wind power can enable green factory operations.

● Supporting a circular economy

Aluminum oxide ceramics play a crucial role in environmentally oriented industrial chains, including new-energy vehicles, photovoltaic encapsulation materials, and electrical insulation components. Resource recovery (e.g., red mud utilization) and recycling of ceramic scrap further promote the development of a sustainable ecosystem.

In summary, aluminum oxide ceramics serve as a bridge to a sustainable future as a “low-carbon, green” material combining high performance with environmental benefits.

Limitations and Constraints

Although aluminum oxide ceramics are widely used across various industries due to their numerous advantages, they also have certain limitations stemming from their physical and chemical properties. Careful consideration and balanced decision-making are required during design and material selection.

● High brittleness: Cracks can propagate easily, and impact resistance is limited, so sudden loads should be avoided.

● Higher machining cost: High-temperature sintering and precision machining require advanced know-how, which can increase difficulty in large-scale manufacturing.

● Relatively high thermal expansion coefficient: When joining with dissimilar materials (e.g., metals), there is a risk of interfacial stress.

● Sensitive to stress concentration and micro-defects: Surface quality and design details significantly affect performance—for example, the flatness of an alumina vacuum chuck directly impacts adsorption precision.

While alumina’s high hardness and stability are major strengths, brittleness, machining complexity, and interfacial compatibility with dissimilar materials should be treated as key design and application challenges.

The best way to maximize alumina performance is to pair it with suitable material selection and appropriate processing and fabrication technologies.

Conclusion

The reason aluminum oxide ceramics are chosen across so many industries is their excellent balance of structural performance, functional properties, and cost. Under demanding industrial conditions—high temperatures, high voltages, corrosive environments, and long service life—alumina is often the optimal material choice. Examples include alumina nozzles with wear and corrosion resistance, insulating components with strong electrical insulation, and vacuum chucks requiring precision adsorption performance—supporting innovation in many forms across industries.

As an integrated solutions provider for advanced materials, JFM has built an industrial value chain covering “material development → process verification → mass production manufacturing → technical support,” and continuously improves alumina process development, sintering/forming, and performance enhancement. We provide interdisciplinary material integration solutions for semiconductor manufacturing, new energy vehicles, medical devices, and more.

Feel free to contact JFM for consultation. We look forward to co-creating high-performance ceramic solutions with you.