What Are the Uses of Alumina?

- 2025-12-29 Industry News

Alumina, also known as aluminum oxide, is a versatile ceramic material widely used across modern industry. This article explores its main applications and uses.

Introduce

You may have heard the term “aluminum oxide,” but do you know what makes it truly valuable? Aluminum oxide (alumina) is an inorganic material with outstanding industrial versatility, deeply connected to many aspects of modern life. From high-performance ceramics and semiconductor substrates to water treatment, artificial joints, and even next-generation batteries as future energy sources, alumina’s applications extend far beyond what most people imagine—playing deeper and increasingly important roles.

So where exactly is alumina used, and why has it become so indispensable?

What Is Aluminum Oxide?

Aluminum Oxide (chemical formula: Al₂O₃) is a white or translucent crystalline powder formed by the bonding of aluminum and oxygen. In nature, it is commonly found as minerals such as corundum, ruby, and sapphire.

It offers high hardness, excellent heat resistance, electrical insulation, corrosion resistance, and strong chemical stability (inertness), making it a key material across many fields.

From an industrial perspective, aluminum oxide can be categorized by application into the following types:

● Metallurgical alumina: the most widely produced type, used in electrolytic extraction of metallic aluminum.

● High-purity alumina: used in advanced technologies such as LED substrates, lithium-ion battery separators, and precision ceramics.

● Activated alumina: used as an adsorbent and filtration media in environmental protection and chemical processes.

Industrial Ceramics: The Foundation of Materials Engineering

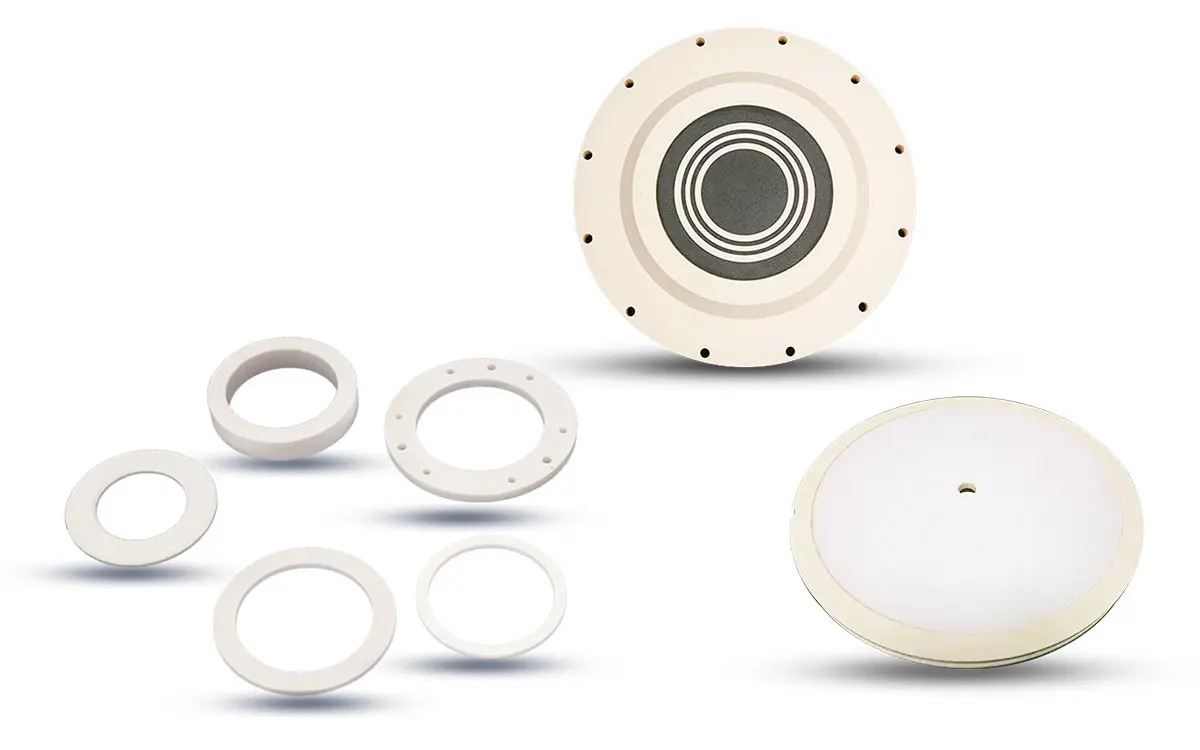

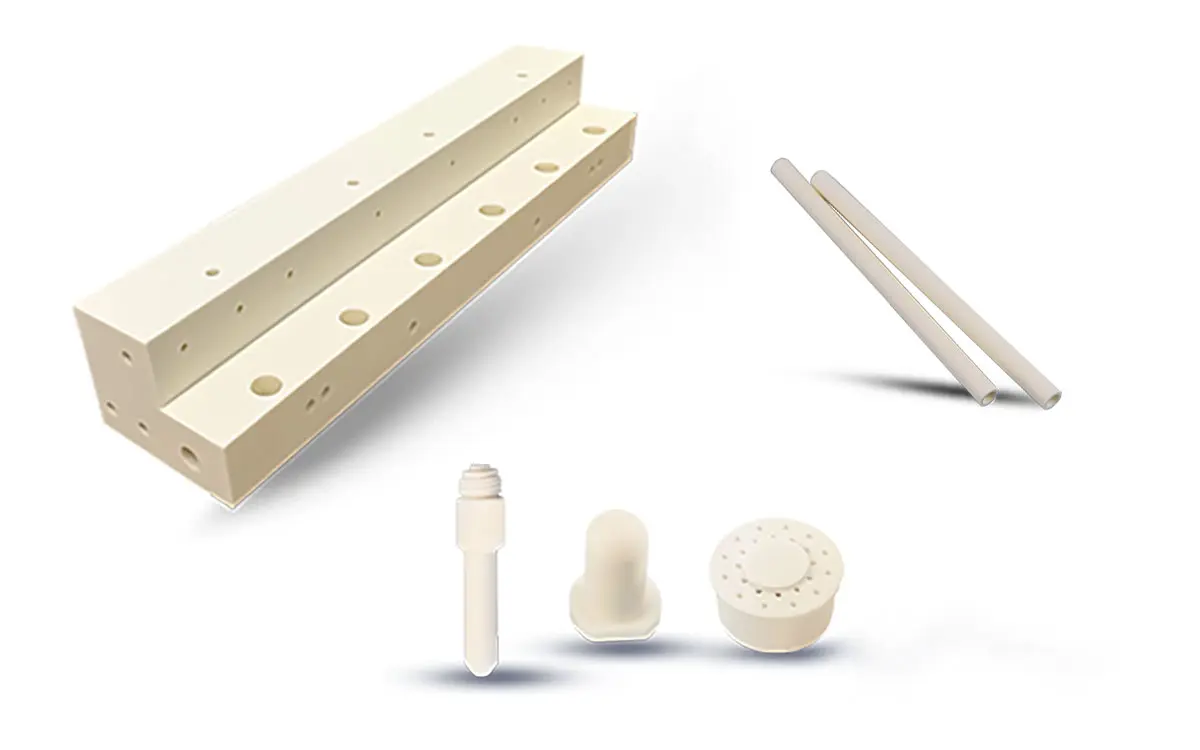

In modern industrial ceramics, alumina (Al₂O₃) has held a crucial position for decades as a structural ceramic material, thanks to its strong overall performance and excellent cost-effectiveness. Especially in harsh environments requiring high load capacity, wear resistance, corrosion resistance, and heat resistance, alumina is widely used to manufacture critical components.

● Friction components such as mechanical seal rings, plain bearings, and bushings

● High wear-resistance components such as nozzles, guide rails, and cutting pads

● Chemical pump housing liners, high-pressure valve components, and mixing impellers

In these applications, alumina (Al₂O₃) is not merely a structural support material—it also plays an important role in stable operation and extending product lifespan. For example, alumina bearings can operate for long periods even without lubricants, greatly reducing maintenance frequency. Likewise, ceramic liners used in chemical pumps prevent metal parts from directly contacting corrosive liquids, lowering leakage risks and reducing the probability of accidents.

Electronics & Semiconductors: Key-Performance Ceramics

In the electronics and semiconductor industries, material stability and functionality directly affect device performance and lifetime. “Alumina (Al₂O₃)” is highly valued as a high-performance electronic ceramic thanks to its excellent electrical insulation, thermal conductivity, and dimensional stability, and it is widely used in many critical processes. Typical applications include:

● Ceramic substrates: used as structural materials for power semiconductor modules, LED lighting, and power control circuits. Low dielectric loss and strong thermal conductivity support stable operation in high-frequency ranges and thermal management.

● Supporting components for electronics manufacturing:

○ Ceramic rings: used to hold wafers or chips during semiconductor processes, enabling stable support and positioning. High hardness and wear resistance help prevent damage during processing.

○ Ceramic vacuum chucks: used for wafer/chip handling and vacuum holding. High-purity alumina meets cleanliness requirements and provides strong, stable vacuum adsorption.

○ Ceramic chamber windows (viewports): used in semiconductor tools, offering heat resistance, corrosion resistance, and optical transmission (when visible inspection is required). Alumina’s stability enables reliable use even under harsh process conditions.

Alumina is also widely used in electronic packaging—for insulating layers, inductor bobbins, thermistor cases, and other fine, high-precision parts. With high machining accuracy and low variation in mass production, alumina has become an essential material supporting device miniaturization, higher speed, and higher reliability.

From consumer electronics to industrial automation control systems, alumina is indispensable for improving device performance, extending product life, and optimizing structural design.

Water Treatment & Air Purification: A Key Material Supporting Environmental Engineering

Alumina (Al₂O₃) also plays an important role in environmental protection—especially in the form of activated alumina, where its functionality is maximized. With high porosity and excellent adsorption performance, alumina is widely used in the following applications:

● Removal of fluoride and arsenic from drinking water: activated alumina effectively reduces concentrations of heavy metals and harmful ions, contributing to safer water supplies.

● Air drying systems: used as a desiccant in compressed air treatment equipment and refrigeration systems.

● Catalyst support in petrochemical and chemical reaction processes: with strong thermal stability and good heat capacity, it is suitable for high-temperature adsorption processes.

Beyond being an adsorbent, alumina can be regenerated via high-temperature calcination or hot-air treatment and reused repeatedly. This reusability not only helps reduce operating costs but also strengthens competitiveness as part of sustainable environmental solutions.

As a functionally tunable and structurally stable material, alumina is deeply integrated into fields such as drinking water treatment, industrial gas purification, and hazardous substance removal—truly a core component of critical environmental systems that are “invisible, yet indispensable.”

Polishing, Grinding & Surface Finishing: A Powerful Tool Essential to Precision Manufacturing

Thanks to its high Mohs hardness, alumina (Al₂O₃)—especially fused alumina and sintered fine powders—is widely used in polishing and grinding processes, serving as a foundational material for high-precision surface finishing in manufacturing.

● Surface finishing of precision metal parts (e.g., molds, machine shafts, blades)

● Polishing of optical components such as glass lenses and sapphire substrates

● CMP (chemical mechanical polishing) of semiconductor silicon wafers

● Deburring and pre-sandblasting for electronic contacts, plated parts, copper/aluminum alloy parts

Alumina particles can be tailored into various forms—blocky, needle-like, spherical, and more—depending on the application. With excellent suspension and dispersion performance, they adapt well to different liquid media. This high customizability allows alumina to serve a broader range of surface treatment applications than traditional corundum or glass beads.

Moreover, alumina is gaining importance in advanced manufacturing technologies such as high-precision mirror finishing, nanometer-level ultra-precision polishing, and functional surface-structure control.

Medical Ceramics: Balancing Durability and Biocompatibility

In orthopedics, dentistry, minimally invasive surgery, and related fields, alumina (Al₂O₃) combines excellent bio-inertness with strong mechanical properties, making it one of the representative materials of modern medical ceramics.

● Ball heads and liners for hip and knee joint replacements

● Wear-resistant substrates for dental implants, crowns, and bridges

● Insulating housings for surgical instruments and minimally invasive intervention guide components

One major advantage of alumina ceramics is their low biological reactivity. They do not leach ions in bodily fluids, do not trigger inflammation, and do not participate in chemical transformations in vivo—showing excellent long-term stability for implantation. In addition, their mechanical strength supports functional requirements under complex physiological conditions.

Today, multiple leading medical device manufacturers have adopted alumina as a key alternative to traditional metals and polymers. Toward longer-lasting and more sustainable medical technologies, alumina applications are gradually expanding into advanced devices such as smart prosthetics.

Chemical & Food Industries: A Clean, Stable, Ideal Material

With high purity and strong inertness, alumina (Al₂O₃) is an important contact material in the chemical and food industries—well suited for long-term use under strict cleanliness standards.

● Anti-corrosion, acid-resistant inner linings for food & beverage containers

● Clean-contact components in pharmaceutical equipment (e.g., reactor linings and fluid control valves)

● High-temperature reaction environments such as research furnaces and quartz tube support parts

Alumina does not leach harmful substances, does not interfere with chemical reactions, and helps suppress microbial growth—making it a more advanced material solution than stainless steel, PTFE, or glass. It also offers strong corrosion resistance, impact resistance, and thermal stability, withstanding relatively demanding continuous chemical reaction processes.

With the growing trend of green manufacturing in the food and pharmaceutical industries, this “quiet and stable” ceramic material is increasingly being adopted as a standard material in many clean-process systems, and alumina applications are expected to continue expanding.

Power & Communications: A Key Material Supporting Stable Transmission

In modern power generation, distribution, and communication networks, insulation, thermal stability, and mechanical strength directly determine system reliability. Thanks to its excellent electrical properties and environmental resistance, alumina (Al₂O₃) is an ideal choice for the following key components:

● High-voltage insulators: used as high-voltage support insulation parts in substations and transmission lines, effectively preventing discharge and flashover phenomena.

● Ceramic ferrules for fiber-optic communications: ensure good fiber end-face alignment and guarantee stable, efficient signal transmission.

● Ceramic supports and feed components for antennas: used in microwave/high-frequency parts in wireless communication systems, combining mechanical strength with thermal insulation.

● Current sensor bases and cable connector insulators: suitable for electrically insulated structures inside complex power equipment.

These alumina applications are critical for maintaining continuous signal transmission and ensuring power-system reliability. With the rapid rollout of next-generation infrastructure such as 5G and smart grids, demand is increasing quickly. Alumina not only provides stable electrical insulation but also offers strong resistance to environmental degradation and mechanical impact, delivering high reliability even outdoors or in harsh operating conditions—cementing its role as a foundational material for modern communications and energy infrastructure.

More Applications of Alumina (Al₂O₃)

Alumina’s capabilities extend beyond traditional industrial uses. Thanks to its high stability, strong structural performance, and functional versatility, it shows broader potential across many specialized industries.

● Ceramic materials for 3D printing

With the advancement of modern manufacturing, alumina is widely used as a powder for ceramic 3D printing—especially for prototyping complex industrial structural parts and orthopedic implant models.

● Watch and jewelry case materials

High-purity alumina crystals (sapphire) are used for watch crystals, camera protective lenses, and jewelry inlays, combining high hardness, excellent transparency, and scratch resistance.

● Refractory and high-temperature insulation materials

Insulation boards, composite mats, and refractory bricks made from alumina fibers are widely used in high-temperature industries such as steel refining, glass melting furnaces, and cement kilns.

● Automotive exhaust emission control systems

In three-way catalytic converters, alumina serves as the main catalyst support framework, providing a stable platform for precious metals such as platinum and palladium, improving exhaust purification efficiency.

● Nail care and daily consumer products

Fine alumina powder provides gentle abrasive effects and is widely used in consumer products such as peeling masks, nail files, and toothpaste.

These diverse applications may look unrelated at first glance, but together they highlight alumina’s dual nature as both a “structural” and “functional” material. In future composite material systems, alumina is expected not only to remain a foundational material but also to play a key role in driving technological progress across many industries.

Conclusion

With the rapid development of advanced technologies such as new energy, flexible electronics, and high-performance composites, the functional potential of alumina (Al₂O₃) continues to expand, steadily penetrating a wide range of emerging application areas. In fields such as lithium batteries, polymer-based composites, and photocatalytic/light-sensitive ceramic technologies, new material characteristics—such as nanostructure control, high specific surface area, transparency, and self-cleaning behavior—are becoming increasingly prominent. This is creating important breakthroughs at the intersection of materials science and environmental technology.

Why Choose JFM

As a comprehensive service provider covering advanced ceramic material R&D through manufacturing, JFM maintains strong material development capability, flexible customization support, and strict quality control—delivering high-purity, multi-specification, application-driven alumina (Al₂O₃) products for a wide range of industries.

● Strict high-purity control: alumina (Al₂O₃) purity up to 99.99%, meeting demanding requirements such as semiconductor-grade and optoelectronic-grade applications.

● Flexible customization: services tailored to diverse needs including particle size, shape, and crystal structure, with project-based development support.

● Cross-industry application capability: proven adoption across electronics, chemicals, environmental systems, and new energy.

● Comprehensive technical support: professional engineers provide material selection guidance, application support, and solutions for performance optimization.

Feel free to contact us for samples or customization discussions. JFM’s alumina ceramics will strongly support your project.