Industrial Applications of Structural Ceramics

- 2026-01-09 Industry News

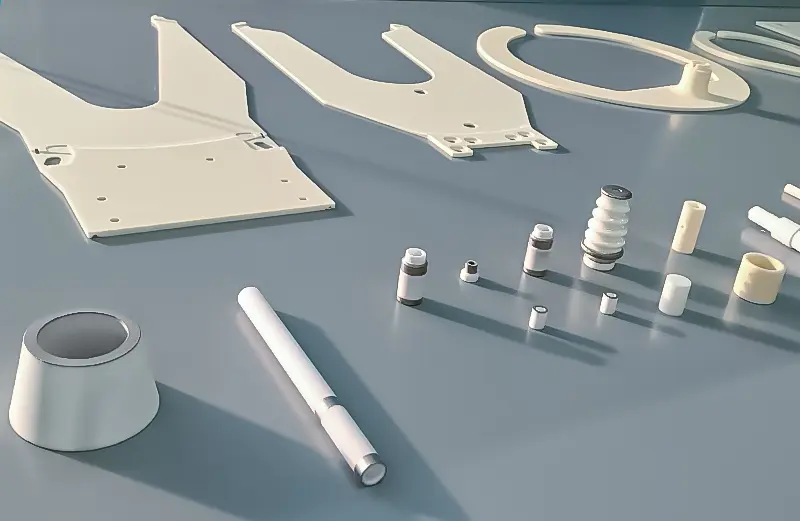

What are structural ceramics? Discover how structural ceramics, with their unparalleled durability and strength, enhance performance across aerospace, energy, and manufacturing industries.

Introduce

Manufacturing is currently evolving toward higher reliability and lower maintenance, and material selection has become a critical factor that greatly affects the performance and service life of equipment. Structural ceramics combine high strength, excellent wear resistance, outstanding thermal stability, chemical stability, and strong electrical insulation — properties that make them a compelling choice for key components across a wide range of fields, including machine and equipment manufacturing, energy systems, and bioengineering. In particular, they play an important role in addressing fatigue failure, which plagues traditional metallic materials, and the lack of heat resistance in many polymer materials.

What are Structural Ceramics?

Structural ceramics are high-performance ceramic materials developed primarily to provide engineering properties such as resistance to mechanical load, wear, high temperatures, and corrosion. These inorganic, non-metallic solids typically form dense, polycrystalline microstructures through high-temperature sintering and exhibit high hardness, strength, elastic modulus, and thermal stability at the macroscopic level. They are mainly used as alternatives to conventional metals and polymers, performing long-term functional and structural roles in machinery, thermal-energy systems, and power systems.

While functional ceramics (such as piezoelectric and dielectric ceramics) emphasize electrical and magnetic responses, structural ceramics prioritize the ability to retain form and deliver stable performance under physical loads (pressure, friction, impact) and chemical environments (corrosion, high-temperature oxidation). Moreover, structural ceramics are a prime example of "modular performance design," in which oxide, nitride, and carbide ceramic systems are combined and tailored according to the intended service environment to achieve optimal performance.

Examples of Structural Ceramics

| Material | Category | Main Properties | Application Areas |

| Alumina (Al₂O₃) | Oxide ceramics | High hardness, excellent wear resistance, and superior electrical insulation | Seals for pumps and valves, electrical insulators, cutting-tool coatings |

| Zirconia (ZrO₂) | Oxide ceramics | High toughness and resistance to crack propagation | Dental and joint implants, impact-resistant components |

| Silicon nitride (Si₃N₄) | Nitride ceramics | High fracture strength and thermal-shock resistance | Bearings, turbines, cutting tools, and components exposed to thermal shock |

| Silicon carbide (SiC) | Carbide ceramics | High thermal conductivity, corrosion resistance, and oxidation resistance at high temperatures | Heat exchangers, nozzles, and fluid-contact components |

| Aluminum nitride (AlN) | Nitride ceramics | Excellent thermal conductivity with high electrical insulation | Power-electronics housings and thermal-management substrates |

The performance of these ceramic systems is influenced by multiple interrelated factors, including grain size, sintered density, phase composition, dopants, and processing methods. For example, some zirconia (ZrO₂) grades utilize a "transformation toughening" mechanism that absorbs crack-propagation energy under stress, achieving fracture toughness far greater than that of conventional ceramics.

Key Properties of Structural Ceramics

Structural ceramics are one of the key elements for improving system reliability, enabling lightweight design, and optimizing operational stability in industrial systems.

High specific strength and high specific modulus

Under equal mass conditions, the load-bearing capability of structural ceramics can significantly exceed that of conventional metallic materials such as titanium alloys or stainless steel, offering excellent mechanical efficiency. Materials such as zirconia (ZrO₂) and silicon nitride (Si₃N₄) can provide structural support while substantially reducing system weight, making them particularly suitable for high-speed moving parts and high-precision structural components where weight is critical.

Controllable coefficient of thermal expansion

Structural ceramics exhibit a wide range of coefficients of thermal expansion that can be precisely tuned through material composition and sintering processes. This enables compatible joints between dissimilar materials, such as metals and semiconductors, and helps prevent interface delamination, cracking, and failure due to thermal-mismatch stress. This property is especially valuable for power modules and sensors where multiple materials are integrated.

Retention of mechanical properties at high temperatures

Many structural ceramics (e.g., SiC, Si₃N₄) retain more than 80% of their room-temperature strength at high temperatures, offering excellent thermal stability and creep resistance. Consequently, they are ideal for high-temperature reaction vessels, gas turbines, and thermal-protection systems.

Extremely high chemical stability

Structural ceramics exhibit exceptional resistance to strong acids, strong alkalis, salt spray, and organic solvents, making them highly corrosion- and degradation-resistant. Therefore, structural ceramics can maintain dimensional stability and mechanical integrity over long periods even in harsh chemical environments, making them optimal choices for chemical reactors, corrosive piping, seals, and filtration systems.

Electronics & Semiconductor

With the advancement of 5G, data infrastructure, and power electronics for new-energy vehicles, the thermal-management and insulation challenges in power semiconductor devices are increasingly prominent. Structural ceramics offer a distinct advantage by combining high thermal conductivity with strong electrical insulation.

Materials and process optimization

Among structural ceramics, aluminum nitride (AlN) combines high thermal conductivity and excellent electrical insulation, making it an ideal material for power-module substrates. Alumina (Al₂O₃) offers stable dielectric properties and chemical resistance, while silicon nitride (Si₃N₄) provides high mechanical toughness and thermal-shock resistance, making it widely used for chip-support frames and substrates.

Moreover, by using processes such as hot pressing and composite sintering, the coefficient of thermal expansion of structural ceramics can be effectively controlled to match semiconductors like silicon and silicon carbide (SiC). This prevents thermal-cycle fatigue and ensures long-term stable operation of electronic devices under complex thermal loads, significantly improving overall system reliability.

Main application components

● Focus rings

● Shield rings

● Edge coils

● Edge rings

● Chamber liners

● Conductive ceramic arms

● Insulators

● Ceramic windows

● Ceramic domes

● Ceramic rails

● Vacuum chucks

Automotive Industry

In modern automotive engineering, materials that combine high-temperature resistance, high strength, light weight, and corrosion resistance are essential for optimizing engine and electric-drive performance. Structural ceramics play a key role in meeting these demands.

Engines and exhaust systems are exposed to temperatures exceeding 800°C, where traditional metals can oxidize, soften, and lose mechanical properties. Structural ceramics, especially SiC and Si₃N₄, meet these requirements with excellent high-temperature and thermal-shock resistance. In addition, the low thermal-expansion coefficients of ceramics reduce thermal-stress buildup and extend component life.

In high-voltage systems for electric vehicles, alumina (Al₂O₃) ceramics are used as insulation components due to their high electrical insulation and mechanical strength, ensuring system reliability. From thermal management to friction control, structural ceramics improve overall vehicle performance, reliability, and durability.

Typical applications

● Ceramic spark-plug insulators

● Ceramic bearings for turbochargers

● Ceramic brake discs

● Ceramic coatings for exhaust manifolds

● Insulating ceramic substrates for electric-drive systems

● Sensor protection covers/housings

Energy Equipment

In energy systems, fluid control and heat-exchange equipment must withstand high temperatures, high pressures, and corrosive media. Structural ceramics, with their excellent corrosion resistance and mechanical strength, are ideal materials for critical components in these systems.

Key materials and processes

Silicon carbide (SiC) is valued for its chemical stability and oxidation resistance and is widely used in gas turbines and nuclear equipment. Zirconia (ZrO₂) and silicon nitride (Si₃N₄) offer high fracture toughness and thermal-shock resistance and are used for valves and seals where wear resistance is required.

Advanced processes such as hot isostatic pressing (HIP) and laser-assisted sintering enable the fabrication of high-density ceramic components with excellent mechanical properties. Surface composite coatings tailored to the service environment can further enhance corrosion resistance.

By reducing equipment downtime caused by wear and corrosion, structural ceramics significantly improve reliability in energy systems.

Primary application parts

● Ceramic valve cores and seats

● Corrosion-resistant pump sleeves and seal rings

● Ceramic plates for high-temperature heat exchangers

● Ceramic insulating layers for reactors

● Fuel-cell support plates and electrolyte layers

● Insulators and separator supports for electrolysis cells

Industrial Machinery Manufacturing

Modern manufacturing demands high precision and efficiency from equipment; the wear resistance, dimensional stability, and thermal stability of parts directly affect production efficiency and product quality. Structural ceramics have become essential materials in machine manufacturing due to their excellent overall performance.

Performance analysis of ceramics

Silicon nitride (Si₃N₄) ceramics are lightweight, tough, and resistant to thermal shock, and are widely used in high-speed rotating parts. Alumina (Al₂O₃) offers cost-effectiveness and good wear resistance, making it suitable for seals and guide rails in corrosive environments. Silicon carbide (SiC) combines wear and corrosion resistance, making it ideal for slurries and other demanding operating conditions.

With high-precision forming and machining techniques, ceramic parts can achieve dimensional tolerances at the micrometer level, meeting demanding equipment-manufacturing requirements and effectively reducing equipment failure rates while stabilizing processing quality.

Concrete ceramic parts

● Ceramic cutting tools (turning, milling, drilling)

● High-speed bearings and linear guides

● Nozzles

● Agitator blades for mixing equipment

● Support components for inspection-platforms

● Ceramic guide sleeves for laser-cutting machines

Life Sciences

Biomaterials for implants must satisfy both biocompatibility and mechanical requirements. Zirconia (ZrO₂), a type of structural ceramic, offers bioinertness, wear resistance, and high mechanical strength, making it suitable for medical devices and restorative materials.

Zirconia ceramics have much higher fracture toughness than conventional ceramics, along with excellent corrosion resistance and stable biocompatibility. Their fine-grained microstructures improve resistance to crack growth, ensuring long-term stability of implants.

Alumina (Al₂O₃) is also used in surgical instruments due to its insulating properties and mechanical strength.

Structural ceramics provide a reliable, long-life material foundation for modern medical devices and help promote advances in clinical technology.

● Examples of medical devices and restorative parts

● Ceramic surface layers for hip and knee implants

● Ceramic crowns and bridges for dental restorations

● Bone screws and bone fasteners

● Ceramic surgical blades

● Oral-implant bases

● Insulating components for medical electronic equipment

Chemical Industry

Process equipment in the chemical industry is constantly exposed to strong acids, strong alkalis, high temperature and pressure, and chemical media; therefore, corrosion resistance and mechanical strength are critical for stable operation. Structural ceramics play indispensable roles in many critical processes due to their excellent chemical inertness and mechanical properties.

Representative ceramics such as silicon carbide (SiC) and alumina (Al₂O₃) are highly corrosion-resistant. SiC ceramics additionally offer high-temperature resistance and strong resistance to acids, alkalis, and organic chemicals, and are widely used for reactor linings and transport systems. Alumina ceramics combine mechanical strength and wear resistance, delivering long-term protection in high-friction environments.

Silicon nitride (Si₃N₄) provides high strength and thermal-shock resistance, reducing equipment downtime for critical reactor components and ensuring production continuity.

Structural ceramic parts achieve uniform thickness and high density through high-precision forming techniques, preventing micro-porosity that can lead to leaks. Their excellent wear resistance reduces maintenance and replacement frequency, thereby minimizing plant downtime and optimizing overall economics and stability.

Representative application parts

● Ceramic linings for reactors

● Lined transport pipes and nozzles

● Pump housings and valve-seal components

● Catalyst substrate supports

● High-temperature insulating layers

● Ceramic cartridges for filters

Conclusion

Structural ceramics are not only performance substitutes for conventional materials but also key drivers for upgrading industrial systems. They deliver unparalleled strength, stability, and reliability under harsh, multi-factor environments and are indispensable across many industries.

JFM leverages long-standing expertise in the field of structural ceramics to provide total solutions, from material selection to forming, processing, and surface treatments. We promote systemization of high-performance ceramic materials and realize optimal solutions tailored to customer needs. For design proposals and engineering support for customized ceramic components, please contact us. JFM is committed to helping your equipment achieve longer life, higher reliability, and optimized performance.